In so-called CADCAM computerized dental technology beside high level aesthetics precision, quickness and use of „human body friendly”materials are carried out at the same time.

Meaning of CADCAM: computer-aided design, computer-aided manufacturing.

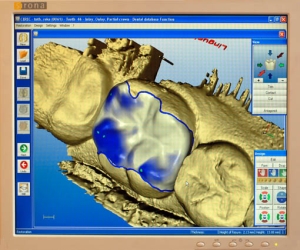

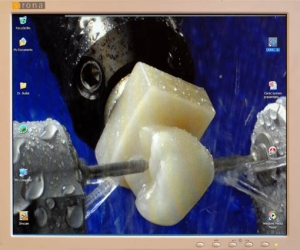

CEREC is a singular patent of German Sirona (Siemens group), it consists of a special device which captures images, and a high-precision micro lathe. An optical impression of the prepared tooth is taken by the special device using an infrared camera, directly from the mouth on the basis of so-called digital, optical scanning, by this way there it is not necessary at all to make a traditional impression. On the basis of this, software makes a 3D virtual model, then design software makes possible to design a virtual tooth restoration, having anatomical conditions, surface of neighbouring teeth and bite in sight. Next step is to select the right ceramic block that matches the tooth colour and size. Its material is an industrially pressed porcelain, its physical qualities are close to natural dental enamel’s parameters, and it is 100% biocompatible. Carving takes less than a quarter of an hour.

Final result is a marvellous and beautiful, quality, human body friendly, lasting dental restoration, all these within 45-50 minutes. The advantage of this are biocompatibility of ceramics, its material qualities (which is the closest material to dental tissue by its physical parameters), its manufacturing technology (ceramic blocks manufactured industrially of lasting quality), software-aided design of high precision (of millimmeters) and one-phase „chairside” treatment (preparation, design, individualization, placing).

CEREC unit makes possible to digitally design and finish zirconium crowns, bridges.

- metal free inlay, onlay, crown, porcelain veneers

- designing and curving zirconium bridge